Understanding the Evolution of Diamond Faceting

Diamond faceting has undergone a significant evolution over the centuries, transitioning from rudimentary methods to intricate, precision-based techniques that are highly dependent on modern technology. The earliest recorded faceting styles, such as the point cut and table cut, reflected basic efforts to enhance the stone’s appearance by improving symmetry and light reflection. However, with time and increasing knowledge of crystallography and optics, faceting techniques have become more advanced and targeted. Today, expert diamond cutters utilize computer-aided design (CAD), laser mapping, and optical modeling to determine the most efficient and aesthetically superior ways to cut a rough diamond. This process not only aims to maximize carat weight and symmetry but also to optimize the diamond’s brilliance, fire, and scintillation. Understanding this evolution is essential for modern professionals, as it sets the stage for more nuanced decisions in advanced cutting methods and design execution.

Precision Planning Through Advanced Mapping Technology

Modern diamond faceting begins long before the physical cutting process. The use of high-resolution 3D laser scanners and X-ray mapping systems, such as Sarine Galaxy and DiaScan, allows gemologists and cutters to analyze inclusions, growth patterns, and internal strain points in rough diamonds. These technologies generate precise models that help experts determine the optimal cut strategy to balance clarity, carat retention, and light performance. Professionals can simulate multiple cutting scenarios digitally to evaluate which plan will deliver the highest return both visually and economically. Advanced software platforms allow users to measure crown angles, pavilion depths, and table ratios with incredible accuracy, reducing the risk of human error during the cutting phase. This level of detail is especially crucial when working with high-value rough stones, where precision dictates final market value. As such, investment in mapping technology is not just a matter of convenience but a competitive necessity in the professional diamond trade.

Laser Cutting and the Shift Toward Microscopic Precision

The advent of laser cutting has redefined the boundaries of what is possible in diamond faceting. Traditional mechanical sawing and bruting methods, while still in use, have been largely supplemented by laser systems that offer unmatched accuracy and minimal material loss. Using high-energy lasers, such as Nd:YAG or fiber lasers, cutters can perform intricate sawing, shaping, and cleaving with sub-millimeter precision. This is particularly beneficial when working with fancy shapes or creating complex facet patterns beyond the standard 57 or 58-facet brilliant cut. Additionally, laser technology is often employed to make fine adjustments in symmetry or to correct issues caused during mechanical cutting. The ability to micromanage each facet angle to within fractions of a degree is invaluable in competitive markets where ideal proportions are closely linked to certification quality and retail pricing. Moreover, laser systems are indispensable in executing techniques such as grooving for tension settings or micro-faceting for light performance enhancement.

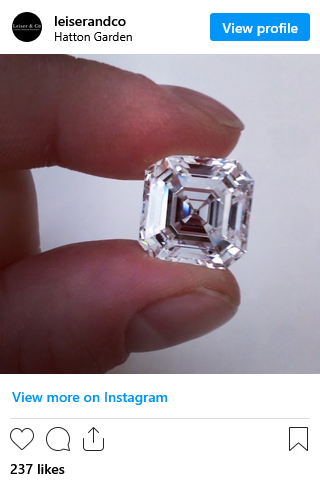

Innovations in Facet Design and Custom Cut Patterns

While traditional faceting styles like the round brilliant and emerald cut remain market staples, there is a growing trend toward bespoke and highly customized faceting patterns. Advanced techniques in facet design enable cutters to experiment with innovative shapes, such as the Crisscut, Royal Asscher, or Hearts and Arrows, which are designed to accentuate specific optical effects. These cuts often require a profound understanding of geometry, crystallography, and optics to ensure optimal performance. Custom facet patterns may include extra pavilion facets, modified girdle shaping, or asymmetric designs intended to cater to modern aesthetic preferences. These innovations are particularly popular in luxury segments and bespoke jewelry commissions, where uniqueness and exclusivity are key selling points. For industry professionals, mastering these unconventional designs not only expands their technical repertoire but also enhances market competitiveness by offering consumers something beyond standardized options. As consumer demand for differentiation increases, so does the relevance of advanced facet design capabilities.

The Science of Light Performance and Optical Precision

A critical component of advanced diamond faceting is understanding and manipulating light performance. This involves the management of three primary optical phenomena: brilliance (white light return), fire (dispersion into spectral colors), and scintillation (flashes of light when the diamond moves). Modern professionals use sophisticated software tools like DiamCalc and Octonus to model how light behaves within a diamond based on facet angles, proportions, and polish quality. These simulations allow cutters to tweak minor variables in their design to maximize light output and minimize leakage. The crown height, pavilion depth, table percentage, and girdle thickness all interact to affect how light enters, reflects, and exits the stone. Even tiny deviations in angle—sometimes as little as one degree—can drastically alter a diamond’s visual appeal. Professionals who specialize in optical engineering can also explore advanced faceting methods like “nano-faceting,” where micro-scale facets are added to improve internal light routing. Understanding this complex interplay between geometry and optics is essential for achieving top-tier results in diamond cutting.

Micro-Faceting and Super-Ideal Cuts: Pursuing Perfection

One of the most sophisticated approaches in modern diamond cutting is the application of micro-faceting and the pursuit of super-ideal cuts. Micro-faceting involves adding ultra-small facets beyond the standard brilliant cut layout to enhance light dispersion and scintillation. These facets are typically imperceptible to the naked eye but significantly impact the diamond’s optical behavior under magnification and specialized lighting. Super-ideal cuts, such as those branded under names like “Hearts and Arrows,” require exacting symmetry and proportion specifications, often verified with optical symmetry viewers and specialized light performance imaging. These cuts are prized not only for their technical perfection but also for their emotional and commercial appeal, especially in high-end retail contexts. To achieve super-ideal quality, professionals must maintain near-zero deviation in all critical angles and ensure that each facet is perfectly aligned. This level of precision requires the integration of computer-controlled cutting systems, expert calibration, and rigorous quality control throughout the cutting process.

Faceting Colored Diamonds and Fancy Colored Stones

Cutting colored diamonds presents a unique set of challenges compared to their colorless counterparts. In colorless stones, the goal is typically to maximize brilliance and light return; in colored diamonds, the objective shifts toward maximizing the intensity and uniformity of color. This requires a different approach to faceting, with special consideration given to pavilion angles and facet arrangements that reduce light leakage and deepen body color. Fancy-colored diamonds, including pinks, blues, and yellows, may benefit from cuts that emphasize saturation, such as radiant or cushion cuts with deep pavilions. Professionals must also consider the role of fluorescence, color zoning, and internal graining when planning the cut. The use of advanced imaging and color modeling tools can assist in predicting how different faceting plans will affect the visual perception of color. Because of the high value and rarity of natural fancy-colored diamonds, cutters often engage in extensive pre-planning and simulations to avoid costly errors and to achieve the most visually impactful result.

Hybrid Cuts and Cross-Disciplinary Design Influence

Another emerging trend in advanced diamond faceting is the creation of hybrid cuts that blend elements from multiple traditional styles. These may include stones that incorporate brilliant, step, and mixed facet arrangements within a single design to achieve a balanced combination of brilliance, depth, and individuality. Hybrid cuts are often inspired by cross-disciplinary influences, including architecture, industrial design, and even biomimicry. Some designers explore patterns that mimic natural forms like leaves, feathers, or geometric tessellations, resulting in uniquely captivating stones. From a technical perspective, these cuts often require a multi-phase cutting approach, where the stone is realigned several times to allow different sections to be cut with distinct faceting styles. These operations demand high technical expertise and often involve collaboration between cutters, CAD designers, and gemological analysts. For professionals seeking to innovate and push creative boundaries, hybrid cuts provide a platform to explore new aesthetic territory while still maintaining optical performance and commercial appeal.

Sustainability and Ethical Innovations in Cutting Practices

As the jewelry industry grows increasingly conscious of sustainability and ethical sourcing, diamond cutting professionals are also embracing more responsible practices. One area of innovation includes reducing material waste through optimized planning software that helps preserve more of the rough stone. Additionally, advancements in cutting technology have enabled a decrease in reliance on water and harsh chemicals traditionally used in polishing processes. Some manufacturers now employ closed-loop systems to minimize environmental impact and recycle resources during the cutting process. Ethical considerations are also driving transparency in cutting practices. Traceability tools, such as blockchain and digital certificates, now document each phase of the cutting journey, from rough sourcing to finished product. For industry professionals, staying updated on sustainable innovations is no longer optional—it is becoming a market expectation. Adopting eco-friendly cutting techniques and being able to demonstrate ethical compliance can open up new opportunities with socially conscious retailers and consumers alike.

Training, Certification, and Continuing Professional Development

Mastering advanced diamond faceting techniques requires more than just access to technology—it demands a deep foundation of knowledge, continuous learning, and often formal certification. Institutions like the Gemological Institute of America (GIA), HRD Antwerp, and IGI offer specialized courses that go beyond basic gemology to cover advanced cutting theory, light performance, and CAD-driven design. For professionals already working in the field, workshops, webinars, and continuing education programs are essential to stay current with rapidly evolving tools and methods. Additionally, peer-reviewed publications, industry conferences, and trade journals provide valuable insights into emerging trends and innovations. In some regions, professional associations offer accreditation systems that validate a cutter’s proficiency in advanced techniques. Maintaining a commitment to professional development not only sharpens technical skills but also enhances credibility and trustworthiness within the global diamond community. Given the competitive nature of the trade, continuous improvement is a cornerstone of long-term success.